About Us

Your Specialist for High-Quality Laser-Cut Cordura Patches

For over 10 years, I have been manufacturing high-quality Laser-Cut Cordura Patches for police, military, security services, emergency responders, outdoor enthusiasts, and tactical medics. My goal is to provide durable, resilient, and precisely crafted patches that remain reliable even in the toughest conditions.

With years of experience in the industry, I understand the essential requirements for tactical and mission-oriented patches: they must not only be robust and durable but also flexible in design, clearly legible, and easy to attach.

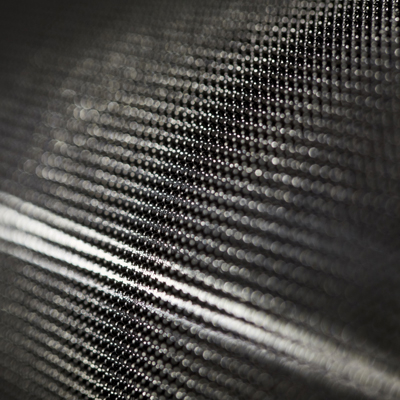

All my patches are made from premium Cordura – a material specifically designed for extreme conditions.

What Materials Are Patches Made Of?

What Is Cordura?

Cordura is a brand name for high-performance fabrics made from nylon, polyester, or a combination of these materials.

-

Durability:

One of Cordura's outstanding features is its exceptional resistance to abrasion, tearing, and impacts. This makes it ideal for applications where durability and protection are essential. -

Water Resistance:

Cordura has a degree of water resistance and dries quickly. This makes it particularly suitable for outdoor gear and clothing exposed to wet conditions.

Features of Laser-Cut Patches

Laser-cut patches are resistant to rain and non-salty water.

Important Notice:

Laser-cut patches should not be washed. Exposure to detergents, hot water, and high temperatures can cause damage.

-

Adhesive Sensitivity:

The adhesive on the back of laser-cut patches can be affected by high temperatures and chemicals. Detergents contain chemical compounds that can weaken or dissolve the adhesive, causing the patch to detach or become damaged. -

Effects of High Washing Temperatures:

Most washing processes use high temperatures to remove dirt and stains. These temperatures can compromise the adhesive and alter the patch's structure. Plastics may melt or deform, resulting in permanent damage to the patch. -

Removing Patches Before Washing:

To ensure longevity, patches should be carefully removed from clothing before washing.

Patches with Velcro

Our patches are standardly delivered with black Velcro backing. If you prefer a patch without Velcro for sewing onto fabric, please inform us before making the payment.

Where Is Cordura Used?

Cordura is widely used in military and outdoor industries due to its abrasion resistance, strength, and water-repellent properties. It is also a popular material for motorcycle clothing and work trousers because of its durability.

What Are the Maximum Patch Sizes?

- Minimum Size: 2.5 × 2.5 cm (25 × 25 mm)

- Maximum Size: 50 × 30 cm (500 × 300 mm)

General Information

- Payment Options: PayPal or bank transfer

- Delivery Time: 1–3 days (the exact delivery time will be individually communicated before payment)

Since our patches are custom-made, returns or complaints are not accepted in the following cases:

- Minor size deviations of up to ±2 mm

- Damage caused by external influences (e.g., washing, sharp objects, chemicals, saltwater)

- Camouflage patterns with slight irregularities in color or design

To prevent loss during shipping, all orders are sent as insured shipments (via Deutsche Post or DHL).

Complaints are accepted if:

- The wrong color or size was delivered

- The stitching is defective

- The text was misprinted

History and Overview of Tactical Patches

Purpose of Patches

Tactical patches serve as quick identification markers, personalization tools for gear, and unit differentiation. They contain relevant information for the wearer and others, making them easily recognizable due to their unique designs.

The history of military insignia dates back centuries. As early as 1810, the British Army introduced insignia to distinguish officer ranks. In the American Civil War of 1862, General Philip Kearny Jr. ordered his troops to wear a piece of red cloth on their caps for easy identification on the battlefield.

During World War I, the 81st Division Wildcats introduced tactical patches to boost troop morale, making them a standard part of military uniforms.

In World War II, the use of tactical patches expanded significantly. Designs became more detailed, and patches contained more information. Even the Walt Disney Company was commissioned to design over 1,200 unique patches featuring popular Disney characters for the US military.

With the development of new materials like nylon and polyester, and the introduction of Velcro, patch application became much easier. This innovation allowed for quick attachment and removal, providing a major advantage in military operations.

Today, tactical patches remain highly relevant in both military and civilian sectors. Many people also collect patches as a hobby, especially in the United States.

Types of Patches

Materials & Manufacturing

There are various types of patches, differing in materials, attachment methods, and functions:

- Woven, embroidered, and printed patches: Traditional styles with fine detailing.

- PVC patches: Extremely durable and weather-resistant, often available in 2D or 3D textures.

- Laser-cut patches: The ideal combination of robustness, durability, and high-quality workmanship. Thanks to precise laser technology, they are particularly resistant to abrasion, moisture, and UV radiation, making them perfect for indoor and outdoor use.

- IR patches: Designed specifically for military use, these patches reflect infrared light and are only visible with night vision devices.

Attachment Methods

- Sew-on patches: For permanent attachment.

- Velcro patches: Easily interchangeable, making them highly practical for tactical applications.

- Adhesive patches: Ideal for temporary use.

Information & Applications

Patches provide quick, clear information at a glance, including:

- Unit affiliation

- Rank insignia

- Medical details such as blood type or allergies

While primarily used by the military, patches are also widely utilized in police forces, fire departments, emergency services, outdoor activities, and clubs.

Functionality of Tactical Patches

Covert vs. Visible Patches

- Covert Patches: These do not reflect visible light and can only be seen with night vision or thermal imaging. They are used for stealth operations and identifying friendly forces.

- Visible Patches: These patches reflect white light and are designed for use in urban environments or low-light situations where visibility is crucial.

In addition to visibility, tactical patches provide critical safety information. They must be clear, legible, and easy to interpret, as they often contain vital details that can be life-saving in emergency situations.

Conclusion: Patches for Every Purpose

Tactical patches play an essential role not only in the military but also in civilian applications. They provide quick and relevant information and can be customized to meet specific requirements.

For more details, visit our website and order your custom-made patches today!