Precision Laser‑Cut Cordura Patches for Professionals

About Us

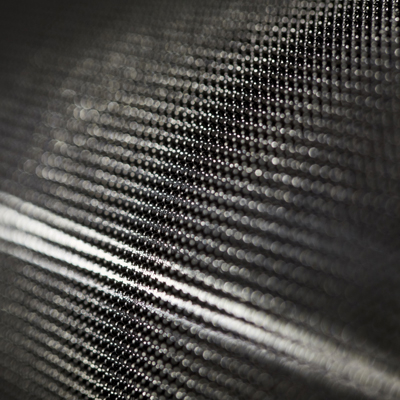

Precision in every thread – Laser-cut Cordura patches that deliver what they promise.

For over a decade, I’ve been crafting custom laser-cut patches made from premium Cordura – designed specifically for police, military, security forces, emergency services, outdoor professionals, and tactical medics. My mission: maximum durability, precise craftsmanship, and uncompromising quality for every field of operation.

With years of experience, I know exactly what tactical patches must deliver:

➡ Extreme durability in harsh conditions

➡ Clear readability day and night

➡ Flexible design tailored to individual needs

Whether it’s a name patch, flag, blood type, or unit insignia – each patch is carefully made from original Cordura and built for professional use. No gimmicks, no mass production – just purpose-driven functionality and outstanding quality.

Properties of Laser-Cut Patches

Laser-Cut Patches are resistant to rain and non-salty water.

Important note:

Laser-cut patches should not be washed. Contact with detergents, hot water, and high temperatures may cause damage.

Adhesive sensitivity:

The adhesive on the back of laser-cut patches may be affected by high temperatures and chemicals. Detergents often contain compounds that can weaken or dissolve the glue, causing the patch to come off or become damaged.

Effect of high washing temperatures:

High temperatures during washing may impair the adhesive or change the patch structure. Plastics may melt or deform, leading to permanent damage.

Remove patch before washing:

To ensure long-lasting performance, always remove the patch from clothing before washing.

Patches with Velcro

Velcro:

Our patches are supplied by default with black Velcro backing. If you prefer a sew-on version without Velcro, please inform us before making payment.

Where is Cordura used?

Cordura is commonly used in military and outdoor applications due to its abrasion resistance, durability, and water-repellent properties. It is also used in motorcycle gear and workwear because of its toughness.

Maximum patch sizes:

-

Minimum size: 2.5 × 2.5 cm (25 × 25 mm) / 0,009'x0,009'

-

Maximum size: 50 × 30 cm (500 × 300 mm) / 20'x12'

General Information:

-

Delivery time: 1–3 days (exact delivery time provided individually before payment)

Since our patches are custom-made, returns are excluded in the following cases:

-

Minor size deviations of up to ±1 mm

-

Damage from external influences (e.g., washing, sharp objects, chemicals, salt water)

-

Camouflage patterns with irregular color variations

To avoid loss during shipping, all orders are sent with insurance (Deutsche Post or DHL).

Returns are accepted only if:

-

A wrong color or size was delivered

-

Stitching is damaged or faulty

-

Incorrect text was printed

History and Overview of Tactical Patches

Function of patches:

Tactical patches are used for quick identification, gear personalization, and unit distinction. They carry relevant information for the wearer and others. With their unique designs, they are highly recognizable and memorable.

Military insignia date back centuries. As early as 1810, the British Army introduced insignias to distinguish officer ranks. During the American Civil War in 1862, General Philip Kearny Jr. used a red piece of cloth for rapid troop identification on the battlefield.

In World War I, the 81st Division Wildcats introduced tactical patches to boost troop morale. Since then, they have become a standard part of military uniforms.

In World War II, tactical patches became even more widespread. They included more detailed information and came in various designs. Even the Walt Disney Company was commissioned to design over 1,200 patches with famous Disney characters for the U.S. military.

With the development of new materials like nylon and polyester, and the introduction of Velcro, patches became easier to handle. These innovations allowed patches to be easily attached, removed, or replaced — a significant advantage in military operations.

Today, tactical patches remain essential in both military and civilian contexts. Many people, especially in the U.S., collect patches as a hobby.

Types of Patches

Material & production:

There are various patch types, differing in materials, mounting, and function:

-

Woven, embroidered, and printed patches: Classic styles with fine detailing

-

PVC patches: Highly durable and weather-resistant, often with 2D or 3D texture

-

Laser-cut patches: The perfect combination of durability, toughness, and clean aesthetics. Thanks to precise laser cutting, they are extremely abrasion-resistant, moisture-proof, and UV-stable — ideal for indoor and outdoor use

-

IR patches: Designed for military use, visible only through night vision by reflecting infrared light

Mounting methods:

-

Sew-on patches: Permanent attachment

-

Velcro patches: Easily interchangeable, ideal for tactical use

-

Adhesive patches: Suitable for temporary use

Information & usage: Patches communicate essential information at a glance, including:

-

Unit affiliation

-

Rank

-

Medical data such as blood type or allergies

Beyond military use, patches are also found in police, fire services, rescue teams, outdoor gear, and clubs.

Purpose of Tactical Patches

Covert vs. visible patches:

-

Covert patches: Do not reflect visible light and can only be seen with night vision or thermal cameras. Used for identifying troops in covert operations.

-

Visible patches: Clearly visible in daylight and reflect white light. Used in urban or standard operations.

Tactical patches also have a safety function. They must be easily readable and understandable, as they may contain critical information in emergencies.

Conclusion: Patches for all purposes

Tactical patches play an important role in both military and civilian applications. They provide quick access to relevant information and can be customized to meet your specific needs.

Visit our website for more information or to order your custom-made patch.